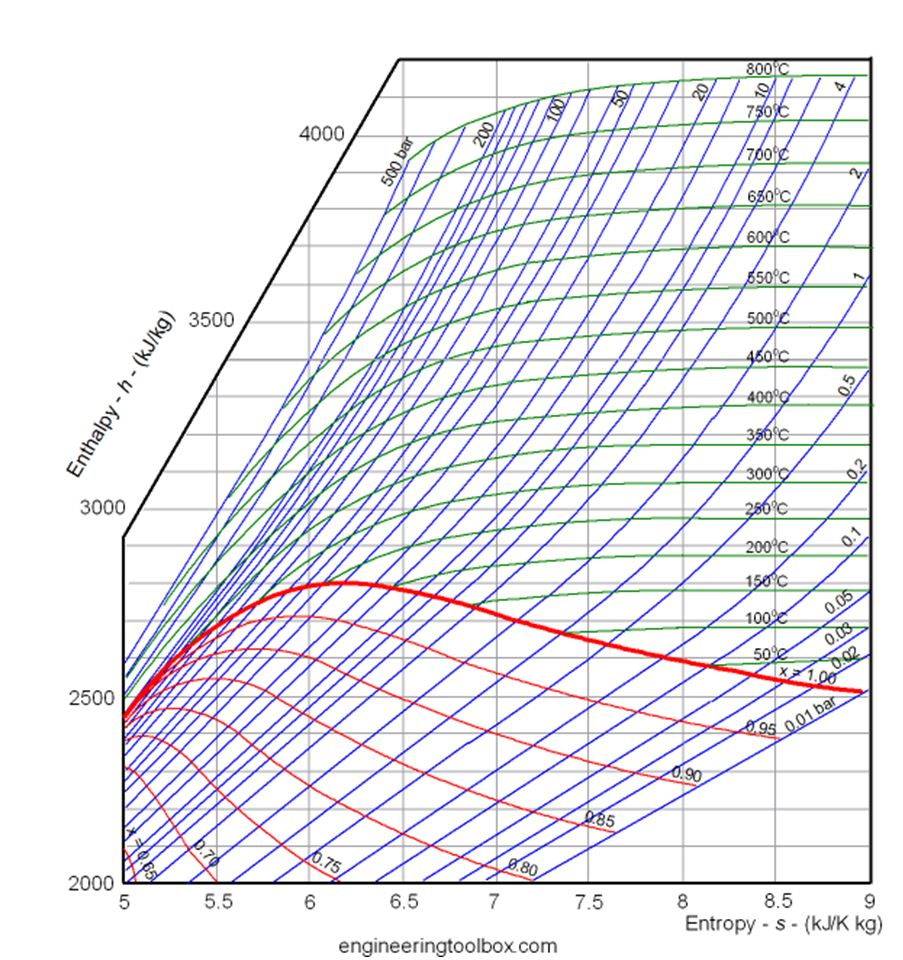

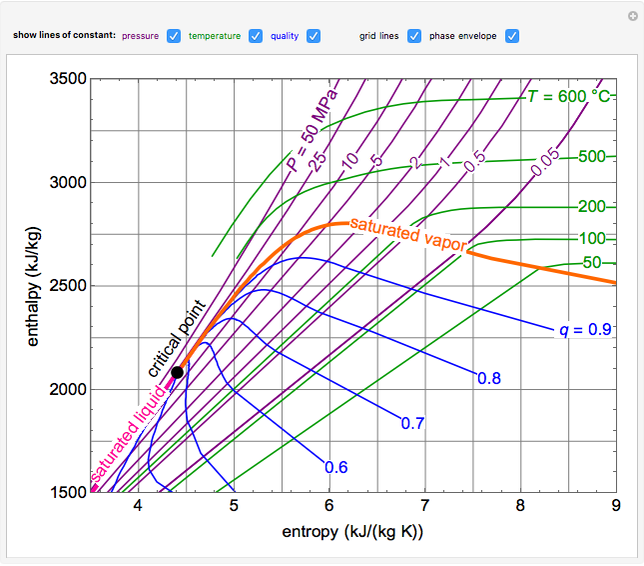

To calculate the enthalpy values, you may use an app or online tool such as. Let's consider a 10 Ton Per Hour boiler is using Rice Husk as fuel. During the process between states 2 and 2 the feedwater is heated and the. More enthalpy means the water contains more energy and thus require less fuel than cold water fed into the system. The higher the temperature of the feedwater the more the enthalpy. On the other hand Rice Husk has the calorific value of around 3300kCal/kg which is less than Hard Coal.Īnother very important thing is the temperature of water we are feeding into the boiler. For example Hard coal has the Gross Calorific Value of 24000kJ/kg or 5736kCal/kg ,means if we burn 1kg of Hard coal we get 5736 kCal of heat. By calorific value we understand how much heat energy we get by burning 1kg of any specific fuel. Some fuels have more energy compared to the others.

Along with the different types of fuel, temperature of the feedwater and the efficiency of boiler the fuel consumption varies.ĭifferent fuels have different calorific values.

Enthalpy of feed water calculator how to#

How to calculate the volume of water required for a gas boiler per 1 m3 of feed. The consumption of fuel depends on a couple of things. With the information you give you can only calculate the enthalpy at the. If the capacity of a boiler is 10TPH or 10TPH F&A (From and At) 100☌ that means the boiler is generating 10 ton of Steam every hour when the water is at 100☌ and at atmospheric pressure. Boiler and fuel types are not considered.Generally the tonnage of a boiler refers to the capacity of a boiler of generating steam per hour.Energy from motors (pumps, fans, etc.) are not considered.Does not include any evaluation of any complex boiler configurations or fluctuations in operation.Blowdown Rate is the % of incoming feedwater mass flow rate that leaves the boiler as a saturated liquid at boiler pressure.containing 40 mole percent methanol and 60 mole percent water into an. Combustion Efficiency is the % of fuel energy that is directly added to the feedwater and not otherwise lost or used. Where, HF, HV and HLare enthalpies of feed, vapor and liquid respectively which.Steam, Boiler, and Blowdown Pressure are the same.Deaerator provides feedwater near the boiling temperature for the deaerator's set operating pressure.This tool calculates the change of the reaction in two ways: 1. Fuel Energy = Boiler Energy / Combustion Efficiency A negative change indicates the reaction is exothermic, while a positive value means it is endothermic.

Boiler Energy = Steam Energy Flow + Blowdown Energy Flow - Feedwater Energy Flow.Blowdown Energy Flow = Specific Enthalpy * Mass Flow.The Specific Enthalpy is then multiplied by the Mass Flow to get the Energy Flow: Using the Steam Property Calculator, properties are determined using Steam Pressure and Quality = 0 (Saturated Liquid). Step 3: Determine Blowdown Properties and Mass Flow Using the calculated feedwater mass flow and blowdown rate: Feedwater Energy Flow = Specific Enthalpy * Mass Flow.The Specific Enthalpy is then multiplied by the Mass Flow to get the Energy Flow: Do a heat balance on the steam condenser to determine the turbine exhaust enthalpy. Using the Steam Property Calculator, properties are determined using Deaerator Pressure and Quality = 0 (Saturated Liquid). Feedwater Mass Flow = Steam Mass Flow /.Steam Mass Flow = Feedwater Mass Flow - Feedwater Mass Flow * Blowdown Rate.

Steam Mass Flow = Feedwater Mass Flow - Blowdown Mass Flow.Blowdown Mass Flow = Feedwater Mass Flow * Blowdown Rate.Step 2: Determine Feedwater Properties and Mass Flow The feedwater flow rate can be calculated from steam mass flow and blowdown rate: Steam Energy Flow = Specific Enthalpy * Mass Flow.Calculation Details and Assumptions belowĬalculation Details Step 1: Determine Properties of Steam Produced Using the Steam Property Calculator, properties are determined using Steam Pressure and the selected second parameter (Temperature, Specific Enthalpy, Specific Entropy, or Quality).

0 kommentar(er)

0 kommentar(er)